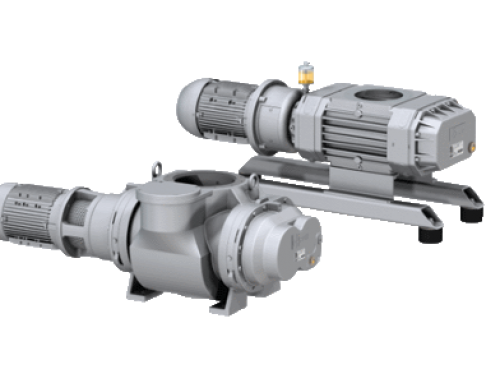

Product Description

Busch Panther Rotary Lobe Blowers

Busch Panter blower is a rotary lobe, positive displacement blower that is designed for either pressure or vacuum applications. Vacuum or pressure is produced by two non-contacting rotors in an oil-free pumping chamber creating a clean, efficient and wear free environment. Wearing parts, such as bearings and gears, are separated from the pumping chamber by labyrinth seals yielding a long service life.

Heavy duty construction and oil lubricated bearings on both the gear end and drive end of the blower ensure reliable operation. The Panther blower features a tri-lobe design that increases efficiency and decreases sound levels.

Features

• Low maintenance

• High efficiency

• Tri-lobe design

• Dry, non-contacting pumping chamber

• Oil lubricated bearings on both ends

• Labyrinth seals

• Heavy duty construction

Operating Principle

The tri-lobe Panther by Busch, works according to the proven rotary lobe principle. Operation is both simple and effective. Two rotors with identical profiles rotate in opposite directions within a casing. As they rotate, air is drawn into the space between each rotor and the casing where it is trapped, transported and discharged by the rotation.

This occurs with each revolution of each rotor and therefore six times for each revolution of the drive shaft. There is no mechanical contact between the rotors and cylinder. Therefore no oil lubrication is required in the pumping chamber.

Standard Equipments

• Rotary lobe blower on base frame

• Discharge silencer • Inlet side silencer

• Motor mounting assembly incl. V-belt drive

• Motor

• Belt guard

Applications

The blower speed and motor size can be selected specifically to suit the exact needs of the following applications:

• Food processing

• Hold down applications

• Lifting and transport systems

• Milking

• Pneumatic conveying

• Soil remediation

• Textile applications

• Waste treatment aeration

• Wood routers